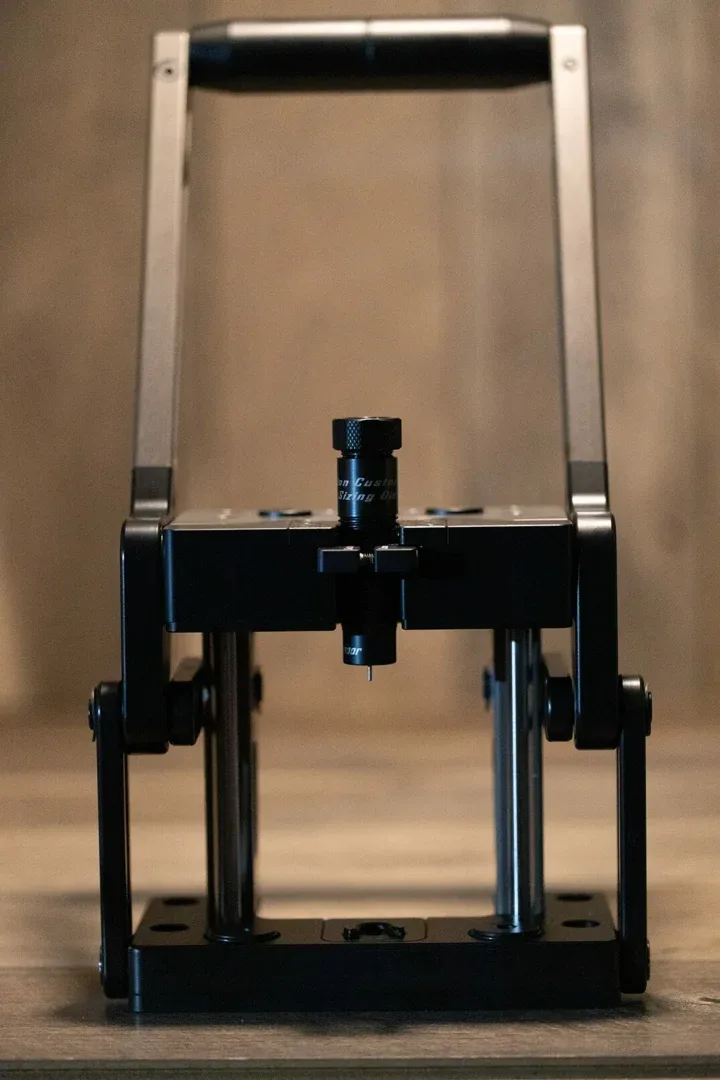

NEXUS PRESS

“THE FOCAL POINT OF YOUR RELOADING PROCESS”

When we set out to develop the Nexus Press, we were trying to build a press that eliminated any type of issues associated with the die and shell holder relationship. We also wanted to develop a more consistent and powerful cam over action every single cycle of he press as well as a work envelope so you can easily and efficiently process your brass without annoying C arms or small work areas in your way. Some of the highly innovative features of the Nexus Press is our dual floating shell holder system, which is also quick change and tool-less. This is similar to the floating bolt head feature of a custom rifle action. The shell holder will center on your die each time because of the “floating” ability of the shell holder. Our shell holder system also allows .010″ more sizing than all other shell holders on the market. So if you are having issues not getting enough sizing out of your dies. No need to modify them anymore, The Nexus Press will take that headache out of the equation. The press is going to include 4 shell holders. 223 Bolt face, 308 Bolt Face, Magnum Bolt face, and Lapua Magnum Bolt face shell holders. Additional shell holders will be available to purchase ala carte. One of the most ground breaking features of the Nexus Press is the dual cam over pucks, which precisely stop the movement of your floating die block every single cycle of the press completely eliminating the relationship between your shell holder and die when it comes to sizing and consistency. One of the issues we discovered when developing the Nexus Press was the need of shell holder contact on the bottom of your die with traditional reloading presses. This causes much stress on your reloading press and sizing or seating die, so we wanted to have The Nexus press cam over totally independently from the shell holder. Every single cycle of the press, your hard cam over pucks limit the travel, which gives you the same amount of cam over every single cycle, regardless of where your die is in relation to the shell holder. The press cams over 2 degrees past top dead center allowing the same amount of sizing or seating with each stroke of the press. The die retention system is completely unique. There are two detents that hold the die in the press, and you can use any standard lock ring that is available on the market today. The die retention system has radial floating capabilities allows your die to center up each time it is used. Additionally the Nexus Press, has storage areas for all your shell holders, dies, or cam over pucks. There are also two 8×32 threaded holes so you can put small brushes to help aide with brass prep. The Nexus Press will easily allow you to run seven-eighths diameter and one-inch diameter dies. To run one-inch diameter dies, you would just simply replace this die retention top plate and that’s it. The 1 inch plates will be available early summer 2024. The Nexus Press uses two precision ground linear guide rods and two linear guide rod bearings. This gives the Nexus Press a very smooth and consistent feel. Every Nexus Press is built to last, we use pre-hardened steels, which are then salt bath nitrided to give us increased strength, lubricity and corrosion prevention. We also use high strength aluminum that is Type III hard coat

anodized. So if you are tired of inconsistencies with your sizing or seating dies, or having to modify your dies to get enough sizing. The Nexus Press is the fix you are looking for!! Just like all of the Short Action Customs products, the Nexus Press comes with a 100% lifetime guarantee.”

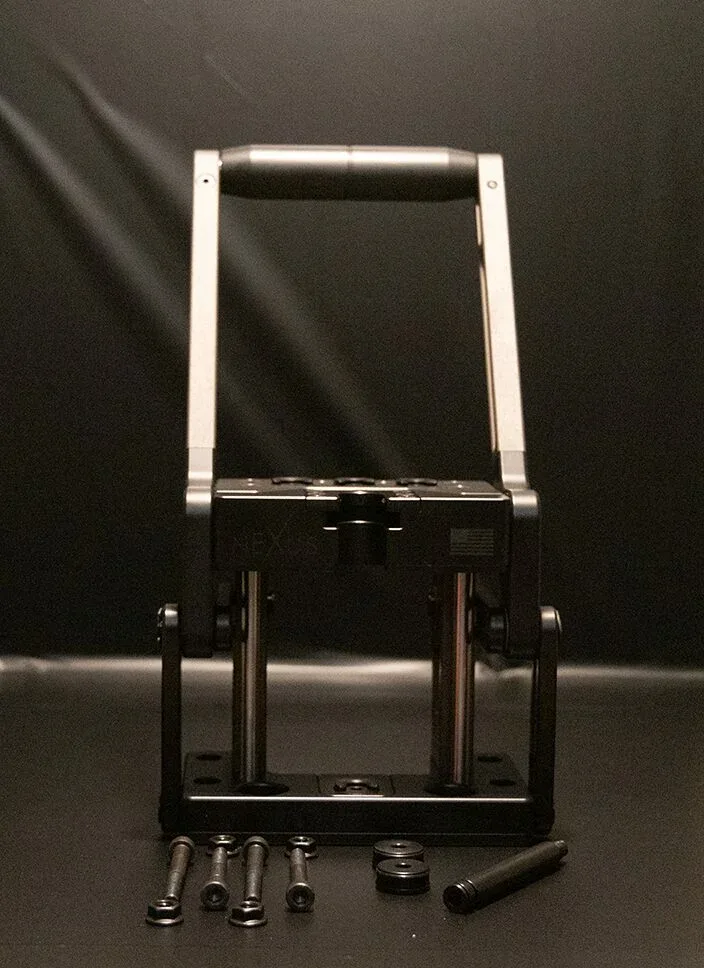

What’s in the box?

- Nexus® Press

- 223 Bolt face Shell holder for cartridges like, 223 Remington, 204 Ruger, 222 Remington, etc

- 308 Bolt face Shell holder for cartridges like 308 Winchester, 6.5 Creedmoor, 6 Dasher, 30-06, etc

- Magnum Bolt face Shell holder for cartridges like 300 PRC, 6.5 PRC, Belted Magnums, RUM’s, Noslers, etc

- Lapua Magnum Bolt face Shell holder for cartridges like 338 Lapua Magnum, 300 Norma Magnum, etc

- Primer Drop Tube

- Template for drilling your bench

- 4 Allen head mounting bolts and nuts

PROUDLY MADE IN THE USA

Next production run is due for July shipment, orders placed are set for this, once full they’ll be later in the year.